近日在美中两国继续竞争,两岸关系紧张之际,另一项国际关注的高科技产品全球缺货,也再度让台湾的名字响亮,再度引起国际瞩目。尤其是,美国总统拜登在一次全国讲话中,更是手中抓着一个小小的东西宣布,这就是美国的马蹄钉,也就是说,缺了它,美国就如同一匹跑不动的马,这个小小的东西就是半导体产品的芯片。而目前全球工业国家都因芯片短缺,导致许多重工业及精密工业的生产活动减缓或停摆。

而台湾正就是全球最大的半导体芯片的设计生产地,《台湾集成电路制造公司》,简称《台积电》,则是全球最大的芯片晶圆生产商。彭博社指出,美國商務部長邀请一些受到到全球晶片短缺影響的企業,将於5月20日舉行視訊高峰會,探討提升因應危機的能力。台灣的台积电也受邀出席峰会。全球晶片短缺也為台積電的業務增添一層政治敏感性。

已于2018年6月宣布退休的台积电创始人董事长张忠谋,自然也就动静观瞻,成为全球工业国家密切关注的工业领导人。 本次中华世界,为大家谈台湾张忠谋的台积电,以及台积电与美国、中国、欧盟,韩国、日本等世界工业国之间的互动。

世现代技术是建立在芯片上的,而台积电的芯片制造技术是最厉害的。

掌握了台积电就掌握了现代技术。美国现代战机和无人机90%的芯片来自台湾。5nm的芯片技术。

据台湾媒体报道,美国F-16和F-35战机的芯片技术重新改进,采用的是台湾的7nm芯片技术。和NVDIA结合后,美国战机的算力已经前所没有。同时出现了很多F-16无人机。

美国很多人在反思,为什么美国人自己生产不出来芯片,他们在假装搞埃米技术芯片。归根到底是美国的工人不行,落后于时代了。

台积电在亚利桑那州建的5nm芯片厂迟迟不能生产,工期一拖再拖。而在日本建立的3nm芯片厂虽然比美国晚,但是还是要提前生产出芯片。

张忠谋一再向美国人强调,美国自己生产不出高阶芯片,你们只要保护好台湾就行。这个老华裔美国人,对美国的制度和台湾的制度知之甚深。

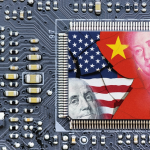

如果中国拿下台湾,就控制了芯片,间接控制了美国。所以美国必须保护台湾。

护国神山的由来.

欧盟准备和台湾发展关系,最主要原因就是台积电。台积电离开台湾就发展不起来了。

高雄的台积电倾整个台湾之力而建!很多事情非公司能干好的。

半导体要进入“埃米时代”了?(这是Intel的宣传,我是不相信intel生产能力比台积电强)

美国英特尔正在加紧开发尖端半导体“Intel 20A ”。20A中的A意为“埃米(angstrom)”。埃米是表示1纳米的10分之1的长度单位,20A指2纳米。英特尔提出新的技术指标,在与台积电(TSMC)和三星电子的竞争中试图扭转劣势。

目前,衡量半导体尖端技术的指标一般使用纳米。具体是指半导体电路的线宽,电路越细半导体的处理能力和数据存储容量越高,还能够抑制电力消耗,并有助于半导体芯片的小型化。半导体厂商一直在竞相推进全是益处的“电路微细化”。

英特尔宣告“埃米时代的到来”,但没有明确说明是长度单位。这只是一个营销口号,目的是彰显先进形象。

那么,现在的线宽指的是什么呢?通常是把单位面积的半导体元件数与过去的自身产品进行比较,根据元件增加了多少来计算。

虽然因为简单易懂而经常被使用,但不能单纯地用这个数值来进行性能比较。还需要关注实际的数据处理能力、数据存储容量、省电性能、订单量等。

芯片在新型战争中的作用非常巨大

美国新任国防部部长说新的战争已经完全和以前不一样了,大部分是无人机的战争。

结合五角大楼提出的第六代战机的雏形,本人总结出美国将对台海用兵的方法 (十年以内):( 埃米时代后,如果台湾技术落后于Intel,我不相信美国有保护台湾的动力)

- 数十个第六代空中航空母机在战争地点3000-4000海里之外;

- 每个航空母机发射出20-60个机载无人飞机;

- 每个机载无人飞机可以发射出10,000-20,000个蜜蜂无人机

- 每个蜜蜂无人机可以定点清除或作为炸药炸船及飞机或一切生命特征的生物。

一切全部利用芯片和空中卫星操作。

本人泄露美国的无人机战略,只是提醒决策者慎重。如果没有先进的芯片技术,海上战争必输无疑。

如果你想胜利,那么就打下3000-4000海里之外的航空母机. 但很有可能那些机载机和无人蜜蜂机的指挥权已经转移给了天上卫星或地面日本,澳大利亚, 韩国,或台湾的基地. 也有可能在潜艇之内.

如果程序编的好, 这些蜜蜂无人机甚至可以不用指挥,根据进攻目标的特点, 发生自杀式炸弹袭击.

量子技术的发展可以侦查到隐形战机,但这些大规模的无人战机不怕被侦查到。

程序员和搬砖者,开发研制FPGA开发板和芯片CPU, 奇门遁甲,阴阳五行,周易八卦的学习者